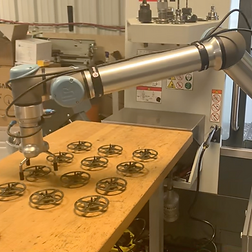

Our Robotic Pick and Place Highlights

A Universal Robots cobot uses vision to pick loosely arranged parts and place them into a machine, and then picks the finished parts and places in an outfeed bin.

For this project, we integrated a Universal Robots UR12e and machine vision to pick metal grommets from a bowl feeder and place them onto another robot’s EOAT for injection molding.

This Universal Robots cobot picks parts and loads them into a drilling machine for machine tending, and offloads the parts after the process is completed.

Benefits of Automated Pick and Place

While manual bin picking is simple, it often slows production and drains labor resources. Operators spend time sorting and positioning parts instead of focusing on higher-value tasks, which leads to frustration and unnecessary labor costs. Automated bin picking solves these issues and adds further benefits by keeping material flowing without constant human intervention.

Increased Throughput

Robots move parts between pick-and-place points with fast, repeatable cycle times and minimal downtime, keeping overall output consistently high.

Improved Quality and Consistency

Automated picking minimizes missed or misplaced parts and delivers uniform placements, improving accuracy and reducing common packing errors.

Integrating Robotic Pick and Place

No two pick and place projects are the same, and no two companies are the same. That's why we offer different approaches to integration. We offer full integration and partial integration, and we also supply components for a cell if you have a team of automation engineers.

Whichever approach fits your needs, we are confident that we can assist. With our long list of pick and place projects, we have the experience and expertise to integrate or assist with a successful pick and place project.

We integrate material removal robots nationwide, with a focus in Dallas, Texas, and Oklahoma.

Get in Contact

If you’d like to explore how robotic pick and place can improve your process, or if you want to discuss your specific application with one of our engineers, reach out and we’ll be in touch to schedule a consultation. We provide full automation integration across the country, with a strong presence in North Texas and Oklahoma.