Our Robotic Machine Tending Highlights

We deployed a cobot to place a small part accurately inside this machine. It utilizes a regrip station so that it can carry out the whole process.

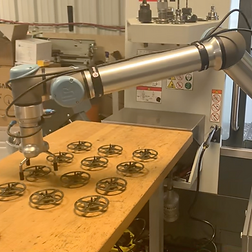

This Universal Robots cobot loads and unloads parts into a drilling machine, and is able to interact with the clamping mechanism inside the machine.

For this press brake application, a cobot uses a suction gripper and orients the part for accurate positioning in the machine.

Benefits of Automated Machine Tending

While simple, manual machine tending can be a costly operation, as operators rack up downtime having to wait for machining processes to finish. Automated machine tending can be a helpful solution to this problem.

Productivity and Efficiency

Robots minimize idle time and downtime by running through breaks and off-shifts, enabling faster load/unload and higher overall throughput.

Labor and Cost Savings

Automation cuts labor for repetitive tasks, frees skilled workers for higher-value work, and reduces exposure to staffing shortages and turnover.

Safety and Ergonomics

Automation lowers injury risk by handling heavy or hazardous tasks, improves ergonomics, and ensures compliance with safety standards.

Integrating Machine Tending Automation

No machine tending projects are the same, and no two companies are the same. That's why we offer different approaches to integration. We offer full integration and partial integration, and we also supply components for a cell if you have a team of automation engineers.

Whichever approach fits your needs, we are confident that we can assist. With multiple machine tending specific projects under our belts, we have the experience and expertise to integrate or assist with a successful machine tending automation project.

We integrate automated machine tending nationwide, with a focus in Dallas, Texas, and Oklahoma.

Schedule an Application Review

Discuss how automation can optimize your machine tending process with one of our engineers. Submit a request and we’ll arrange a brief discovery call at your convenience. We provide full automation integration across the country, with a strong presence in North Texas and Oklahoma.